close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

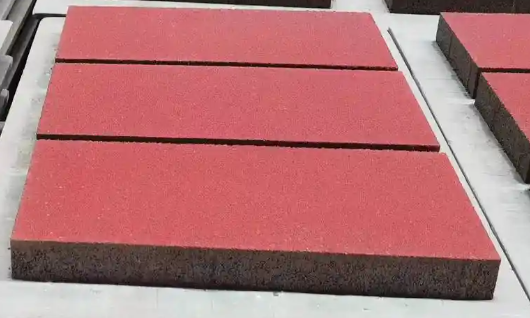

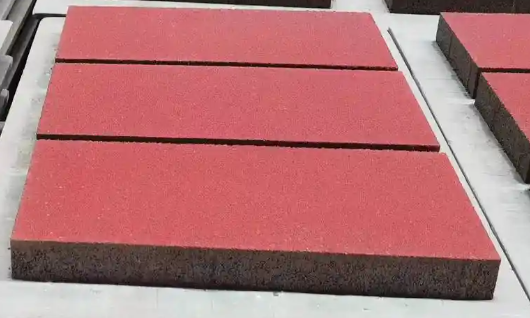

flat cover plastic mold

wangzu

Product introduction

Plastic cover plate molds are industrial molds used for manufacturing precast concrete components such as drainage ditch covers and cable trench covers. They are mainly made of materials like polypropylene (PP) or ABS resin through injection molding processes. Here are the key points:

Materials and Structure

Materials: Polypropylene (PP) or ABS resin, which are corrosion-resistant and recyclable. Some large-sized molds are made of a composite material of sheet metal and steel.

Structure: Split-body combination design, including a detachable upper shell and a fixed frame. Some models support length adjustment (10-50 cm).

Process and Performance

Forming Process: Injection molding or compression molding, combined with a vibration platform for bubble removal to ensure the density of the component.

Durability: The turnover rate can reach 200 to 300 times, and the proportion of ABS engineering plastic molds is up to 45% (data for 2025).

Application fields

Transport infrastructure: Highway drainage ditch covers (accounting for 62%), railway cable trench covers (accounting for 28%).

Municipal engineering: manhole covers for urban utility tunnels, pavement covers for sidewalks.

Special scenarios: Port load-bearing covers (load ≥ 80 tons), airport isolation strip covers.

The technological innovation in 2024's utility model patent (CN220***890U) adopts a worm gear and worm transmission mechanism. A single set of molds can be adapted to 3 to 5 specifications, reducing the mold reserve by 30%.

Product Advantage

The plastic cover plate mold is a core equipment used in municipal, road, power and other engineering projects for prefabricating concrete cover plates. Its advantages mainly lie in lightweight, high efficiency, durability and cost control. Here is a detailed analysis:

Lightweight and easy to transport

Material: Made of high-strength PP/ABS plastic, each set of molds weighs only 10-25kg and can be easily moved by hand. It is particularly suitable for construction in complex terrains.

Modular design: Snap-fit assembly structure, no tools required for quick assembly, completed by one person within 30 minutes.

Efficient molding and precision

Molding efficiency: 25-30 standard cover plates can be preformed per day, and the demolding time is reduced to 2 hours, with the efficiency increased by 50% compared to traditional processes.

Precision control: The flatness error of the inner cavity is ≤ 0.8mm, the dimensional accuracy is ± 0.5mm, and it is compatible with various specifications (300×500mm to 1000×2000mm).

Durability and Environmental Friendliness

Service Life: The ABS plastic mold has a lifespan of over 8 years and can be reused for more than 50 times, which is 4 times longer than that of wooden molds.

Environmental friendliness: It can be 100% recycled after disposal, reducing the project cost by 20%. 2

Wide application scope

Applicable scenarios: Widely used in municipal drainage, residential roads, power wells renovation, etc., meeting different load and span requirements.

Function optimization: Pre-set the positioning slots for reinforcing bars and the drainage holes, reducing the need for additional processing.

Cost advantage

Low cost: Compared to cast iron covers, the project cost is reduced, and the maintenance cost is also lower (such as the heat-dip galvanizing anti-corrosion design).

Technical Parameter

| Model | Plastic cover plate mold |

| Material | PP |

| Quality Control | We have QC system and record all production process for your review |

| Brand | Wangzu |

| Shape | square rectangle |

| Loading Port | Shanghai/Zhapu |

Product use

FAQ

Q1.Is your company a manufacturer or a trader? We are the proud manufacturers with over a decade of unparalleled production experience.

Product introduction

Plastic cover plate molds are industrial molds used for manufacturing precast concrete components such as drainage ditch covers and cable trench covers. They are mainly made of materials like polypropylene (PP) or ABS resin through injection molding processes. Here are the key points:

Materials and Structure

Materials: Polypropylene (PP) or ABS resin, which are corrosion-resistant and recyclable. Some large-sized molds are made of a composite material of sheet metal and steel.

Structure: Split-body combination design, including a detachable upper shell and a fixed frame. Some models support length adjustment (10-50 cm).

Process and Performance

Forming Process: Injection molding or compression molding, combined with a vibration platform for bubble removal to ensure the density of the component.

Durability: The turnover rate can reach 200 to 300 times, and the proportion of ABS engineering plastic molds is up to 45% (data for 2025).

Application fields

Transport infrastructure: Highway drainage ditch covers (accounting for 62%), railway cable trench covers (accounting for 28%).

Municipal engineering: manhole covers for urban utility tunnels, pavement covers for sidewalks.

Special scenarios: Port load-bearing covers (load ≥ 80 tons), airport isolation strip covers.

The technological innovation in 2024's utility model patent (CN220***890U) adopts a worm gear and worm transmission mechanism. A single set of molds can be adapted to 3 to 5 specifications, reducing the mold reserve by 30%.

Product Advantage

The plastic cover plate mold is a core equipment used in municipal, road, power and other engineering projects for prefabricating concrete cover plates. Its advantages mainly lie in lightweight, high efficiency, durability and cost control. Here is a detailed analysis:

Lightweight and easy to transport

Material: Made of high-strength PP/ABS plastic, each set of molds weighs only 10-25kg and can be easily moved by hand. It is particularly suitable for construction in complex terrains.

Modular design: Snap-fit assembly structure, no tools required for quick assembly, completed by one person within 30 minutes.

Efficient molding and precision

Molding efficiency: 25-30 standard cover plates can be preformed per day, and the demolding time is reduced to 2 hours, with the efficiency increased by 50% compared to traditional processes.

Precision control: The flatness error of the inner cavity is ≤ 0.8mm, the dimensional accuracy is ± 0.5mm, and it is compatible with various specifications (300×500mm to 1000×2000mm).

Durability and Environmental Friendliness

Service Life: The ABS plastic mold has a lifespan of over 8 years and can be reused for more than 50 times, which is 4 times longer than that of wooden molds.

Environmental friendliness: It can be 100% recycled after disposal, reducing the project cost by 20%. 2

Wide application scope

Applicable scenarios: Widely used in municipal drainage, residential roads, power wells renovation, etc., meeting different load and span requirements.

Function optimization: Pre-set the positioning slots for reinforcing bars and the drainage holes, reducing the need for additional processing.

Cost advantage

Low cost: Compared to cast iron covers, the project cost is reduced, and the maintenance cost is also lower (such as the heat-dip galvanizing anti-corrosion design).

Technical Parameter

| Model | Plastic cover plate mold |

| Material | PP |

| Quality Control | We have QC system and record all production process for your review |

| Brand | Wangzu |

| Shape | square rectangle |

| Loading Port | Shanghai/Zhapu |

Product use

FAQ

Q1.Is your company a manufacturer or a trader? We are the proud manufacturers with over a decade of unparalleled production experience.