close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

Plastic mold

wangzu

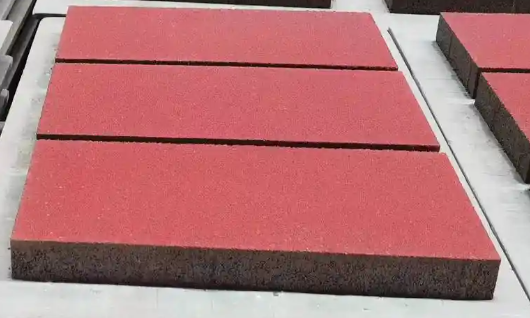

Product introduction

Plastic cover plate molds are industrial molds used for manufacturing precast concrete components such as drainage ditch covers and cable trench covers. They are mainly made of materials like polypropylene (PP) or ABS resin through injection molding processes. Here are the key points:

Materials and Structure

Materials: Polypropylene (PP) or ABS resin, which are corrosion-resistant and recyclable. Some large-sized molds are made of a composite material of sheet metal and steel.

Structure: Split-body combination design, including a detachable upper shell and a fixed frame. Some models support length adjustment (10-50 cm).

Process and Performance

Forming Process: Injection molding or compression molding, combined with a vibration platform for bubble removal to ensure the density of the component.

Durability: The turnover rate can reach 200 to 300 times, and the proportion of ABS engineering plastic molds is up to 45% (data for 2025).

Application fields

Transport infrastructure: Highway drainage ditch covers (accounting for 62%), railway cable trench covers (accounting for 28%).

Municipal engineering: manhole covers for urban utility tunnels, pavement covers for sidewalks.

Special scenarios: Port load-bearing covers (load ≥ 80 tons), airport isolation strip covers.

The technological innovation in 2024's utility model patent (CN220***890U) adopts a worm gear and worm transmission mechanism. A single set of molds can be adapted to 3 to 5 specifications, reducing the mold reserve by 30%.

Technical Parameter

| Model | Plastic cover plate mold |

| Material | PP |

| Quality Control | We have QC system and record all production process for your review |

| Brand | Wangzu |

| Shape | square rectangle |

| Loading Port | Shanghai/Zhapu |

Product use

FAQ

Q1.Is your company a manufacturer or a trader? We are the proud manufacturers with over a decade of unparalleled production experience.

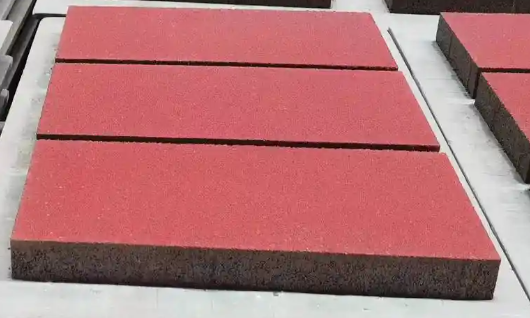

Product introduction

Plastic cover plate molds are industrial molds used for manufacturing precast concrete components such as drainage ditch covers and cable trench covers. They are mainly made of materials like polypropylene (PP) or ABS resin through injection molding processes. Here are the key points:

Materials and Structure

Materials: Polypropylene (PP) or ABS resin, which are corrosion-resistant and recyclable. Some large-sized molds are made of a composite material of sheet metal and steel.

Structure: Split-body combination design, including a detachable upper shell and a fixed frame. Some models support length adjustment (10-50 cm).

Process and Performance

Forming Process: Injection molding or compression molding, combined with a vibration platform for bubble removal to ensure the density of the component.

Durability: The turnover rate can reach 200 to 300 times, and the proportion of ABS engineering plastic molds is up to 45% (data for 2025).

Application fields

Transport infrastructure: Highway drainage ditch covers (accounting for 62%), railway cable trench covers (accounting for 28%).

Municipal engineering: manhole covers for urban utility tunnels, pavement covers for sidewalks.

Special scenarios: Port load-bearing covers (load ≥ 80 tons), airport isolation strip covers.

The technological innovation in 2024's utility model patent (CN220***890U) adopts a worm gear and worm transmission mechanism. A single set of molds can be adapted to 3 to 5 specifications, reducing the mold reserve by 30%.

Technical Parameter

| Model | Plastic cover plate mold |

| Material | PP |

| Quality Control | We have QC system and record all production process for your review |

| Brand | Wangzu |

| Shape | square rectangle |

| Loading Port | Shanghai/Zhapu |

Product use

FAQ

Q1.Is your company a manufacturer or a trader? We are the proud manufacturers with over a decade of unparalleled production experience.