close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

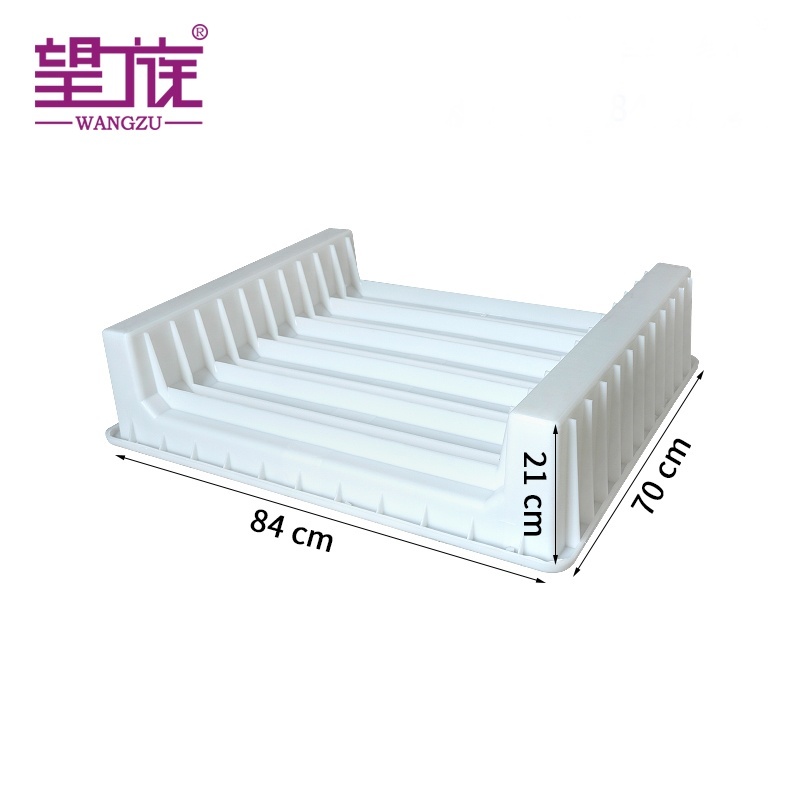

82*48.5*21

Wangzu

The cable trough mold is a specialized tool used for manufacturing prefabricated concrete cable troughs. It is mainly made of steel plates or engineering plastics and is widely applied in cable protection projects such as highways and high-speed railways.

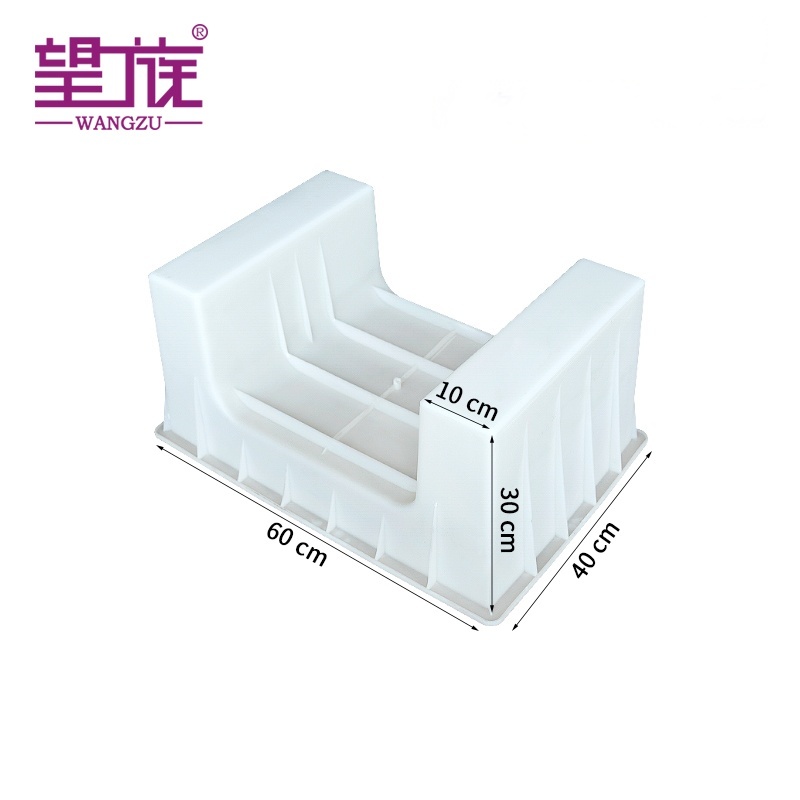

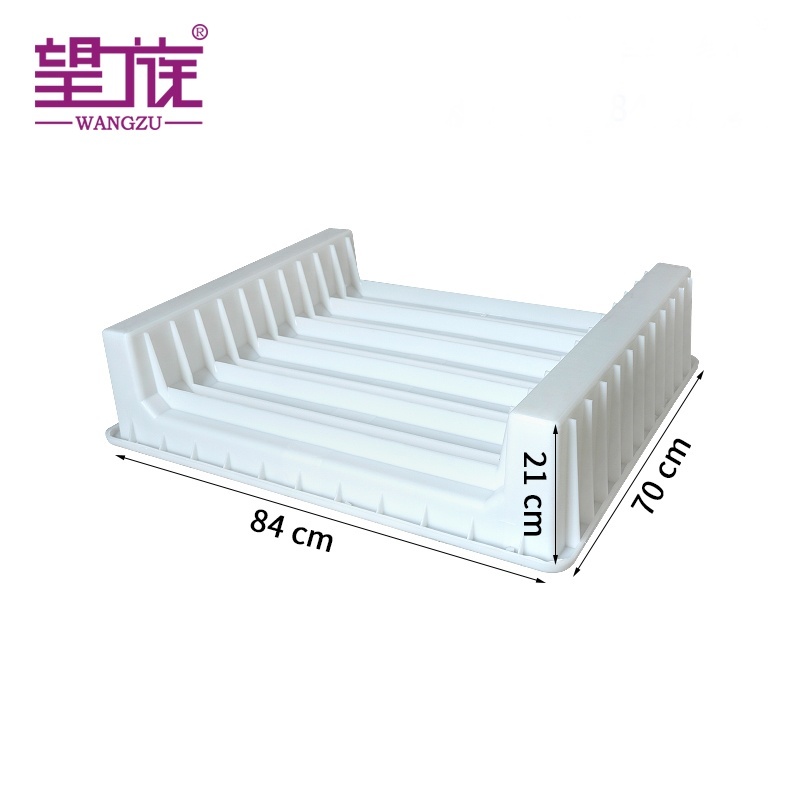

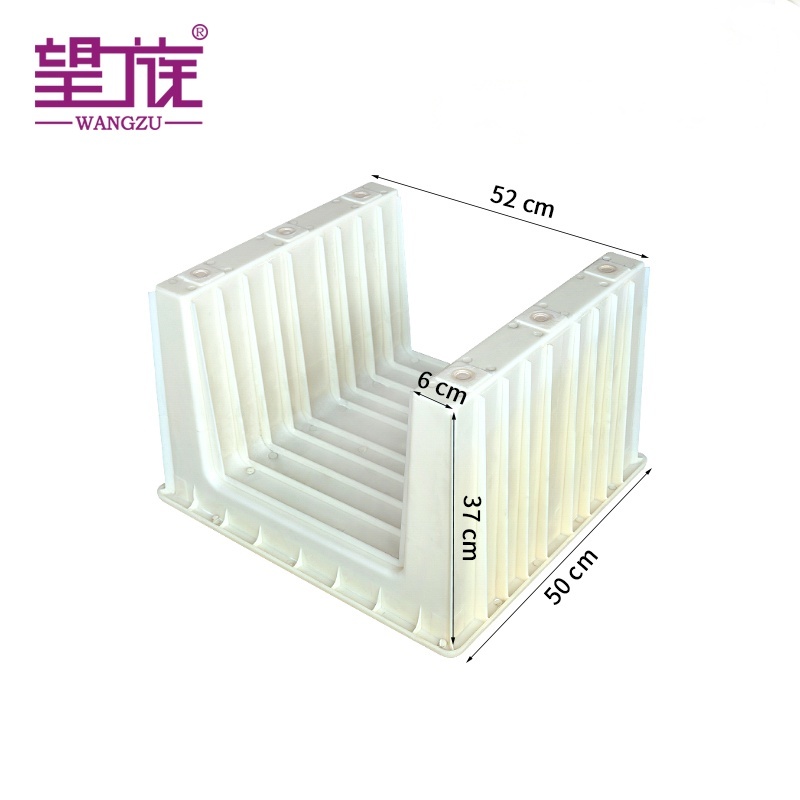

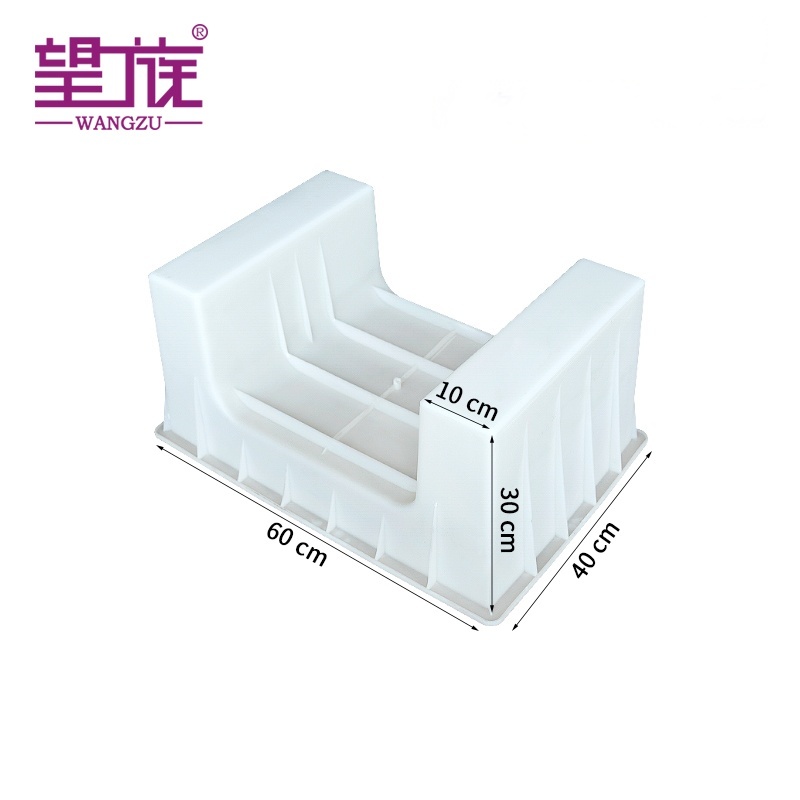

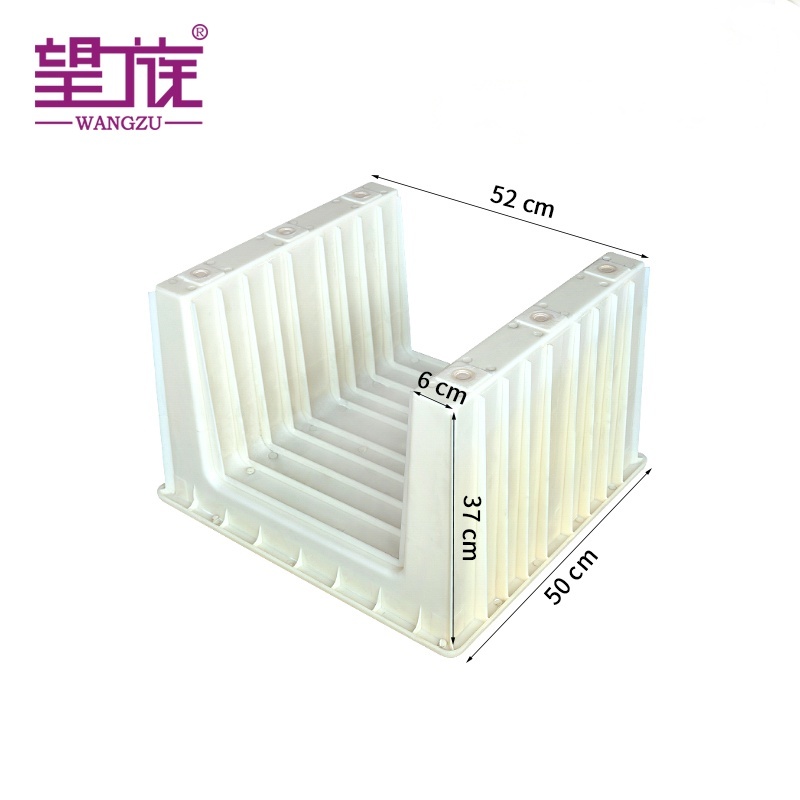

The mold structure is mostly U-shaped or rectangular. The split design makes it convenient for assembly and disassembly. The side mold and the bottom mold are connected by snap fasteners, and the disassembly time can be shortened to 10 minutes per set. Common specifications include 900mm×500mm×375mm and 1000mm×500mm×375mm, with an inner wall smoothness of Ra1.6 to ensure that the cables are not damaged during laying.

Plastic mold: It is injection molded with ABS resin or polypropylene (PP), and its weight is only 1/3 of that of the steel mold. It has the characteristics of smooth demolding, high surface finish, and corrosion resistance, and is suitable for small batch customization.

1. Insulation and Flame Retardancy: The PVC material has high resistance properties, reducing the risk of leakage; with a high oxygen index, it does not self-ignite and can effectively prevent the spread of fire.

2. Mechanical Strength and Corrosion Resistance: The structure is sturdy, with excellent pressure resistance and impact resistance, suitable for acidic and alkaline environments, and does not age easily over time.

3. Installation Convenience: The bottom of the slot and the cover are combined and fastened tightly, with a smooth joint surface, supporting quick disassembly and flexible wiring.

| Brand: | Wangzu |

| Material: | Polypropylene/Acrylonitrile Butadiene Styrene |

| Color: | White/Yellow |

| Shape: | Box |

| Feature: | Using new materials,labor saving section superior quality,flexible and convenient,safety and environment protection |

Factory buildings and workshops

Rairoad engineering

……

The cable trough mold is a specialized tool used for manufacturing prefabricated concrete cable troughs. It is mainly made of steel plates or engineering plastics and is widely applied in cable protection projects such as highways and high-speed railways.

The mold structure is mostly U-shaped or rectangular. The split design makes it convenient for assembly and disassembly. The side mold and the bottom mold are connected by snap fasteners, and the disassembly time can be shortened to 10 minutes per set. Common specifications include 900mm×500mm×375mm and 1000mm×500mm×375mm, with an inner wall smoothness of Ra1.6 to ensure that the cables are not damaged during laying.

Plastic mold: It is injection molded with ABS resin or polypropylene (PP), and its weight is only 1/3 of that of the steel mold. It has the characteristics of smooth demolding, high surface finish, and corrosion resistance, and is suitable for small batch customization.

1. Insulation and Flame Retardancy: The PVC material has high resistance properties, reducing the risk of leakage; with a high oxygen index, it does not self-ignite and can effectively prevent the spread of fire.

2. Mechanical Strength and Corrosion Resistance: The structure is sturdy, with excellent pressure resistance and impact resistance, suitable for acidic and alkaline environments, and does not age easily over time.

3. Installation Convenience: The bottom of the slot and the cover are combined and fastened tightly, with a smooth joint surface, supporting quick disassembly and flexible wiring.

| Brand: | Wangzu |

| Material: | Polypropylene/Acrylonitrile Butadiene Styrene |

| Color: | White/Yellow |

| Shape: | Box |

| Feature: | Using new materials,labor saving section superior quality,flexible and convenient,safety and environment protection |

Factory buildings and workshops

Rairoad engineering

……