close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

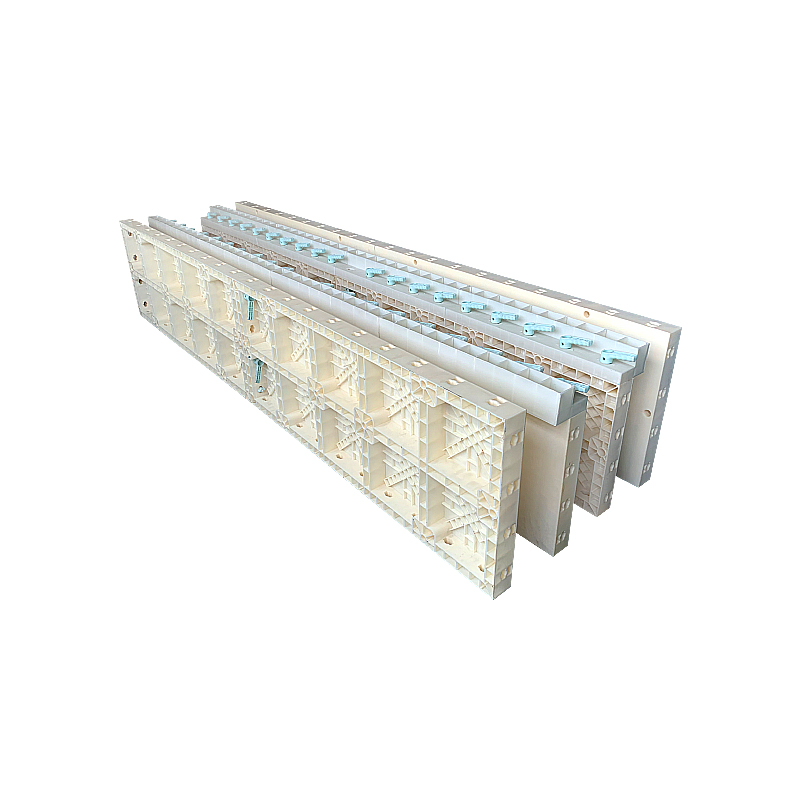

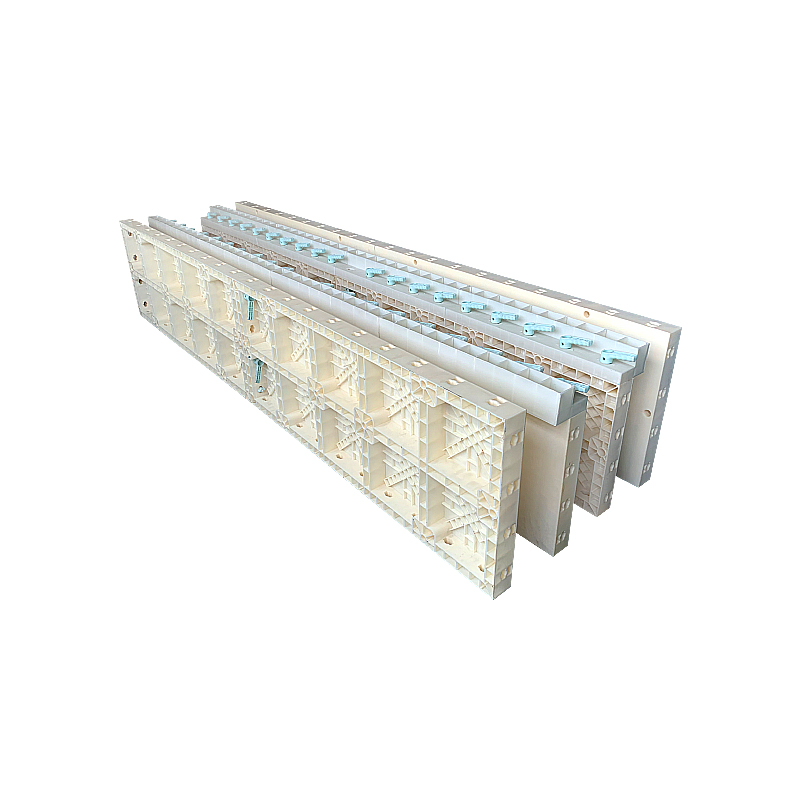

Pouring The Construction Formwork for The Dam Project

Wangzu

Product introduction

Building plastic formwork is a temporary supporting structure made of plastic. It is mainly used to maintain the shape of concrete during the concrete pouring process and prevent leakage and cracks.

Common types

plastic formwork : Made of fiber-reinforced thermoplastic (such as polypropylene), it enhances structural strength by adding plant fibers and is suitable for pouring concrete of complex shapes.

Polymer composite material templates: For instance, the polymer material templates developed by Katie Vincent have high strength and weather resistance, and can be reused.

Product Advantage

Cost-effectiveness: Compared to traditional wood or steel formwork, plastic formwork has a longer service life and lower maintenance costs.

Construction efficiency: Lightweight and easy to transport, suitable for high-rise buildings and complex structural construction.

Environmental protection features: Some products are recyclable, reducing construction waste.

Application scenario

It is mainly used in projects such as bridges, high-rise buildings, and underground engineering where precise control of concrete molding is required.

Technical Parameter

| Brand | Wangzu |

| Model | Gutter Plastic formwork |

| Material | PP/ABS |

| Size | 150*30*8 |

Product Use

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are a dedicated manufacturing factory.

Q2: What services do you offer?

A: We specialize in the innovative design and robust manufacturing of formwork and scaffolding solutions. These are pivotal in the construction of concrete structures across a variety of projects, including residential properties, multi-level complexes, towering skyscrapers, elegant towers, expansive sports stadiums, intricate bridges, hydropower units, and diverse industrial structures.

Q3: How can we assist you?

A: We provide expert advice, meticulous formwork layout plans, and comprehensive cost estimations to stakeholders such as project owners, architectural design institutes, and construction contractors.

B: Our products are available for purchase by contractors, construction companies, material suppliers, and trading entities.

C: We extend support to our global partners with our high-quality formwork and scaffolding products.

D: We offer both remote and on-site guidance to construction teams to ensure flawless execution.

Q4: Can you provide samples? Are they complimentary?

A: Absolutely, we offer complimentary samples; however, the cost of freight is not included.

Q5: What information is required to draft a preliminary design and quotation for a construction project?

A: We need the structural and sectional drawings.

Q6: How long does it generally take to formulate a brief design and quotation once we provide the structural drawings?

A: Typically, it requires about 5 to 7 days, contingent upon the specific needs of the construction project.

Q7: What is the estimated timeframe for manufacturing the products after the contract is signed?

A: Generally, the production period ranges from 30 to 60 days, depending on the type and volume of products ordered.

Q8: Could you explain your payment terms?

A: For payments up to 1000 USD, full payment is required in advance. For payments exceeding 1000 USD, a 30% T/T deposit is necessary, with the remaining balance due before shipment.

Product introduction

Building plastic formwork is a temporary supporting structure made of plastic. It is mainly used to maintain the shape of concrete during the concrete pouring process and prevent leakage and cracks.

Common types

plastic formwork : Made of fiber-reinforced thermoplastic (such as polypropylene), it enhances structural strength by adding plant fibers and is suitable for pouring concrete of complex shapes.

Polymer composite material templates: For instance, the polymer material templates developed by Katie Vincent have high strength and weather resistance, and can be reused.

Product Advantage

Cost-effectiveness: Compared to traditional wood or steel formwork, plastic formwork has a longer service life and lower maintenance costs.

Construction efficiency: Lightweight and easy to transport, suitable for high-rise buildings and complex structural construction.

Environmental protection features: Some products are recyclable, reducing construction waste.

Application scenario

It is mainly used in projects such as bridges, high-rise buildings, and underground engineering where precise control of concrete molding is required.

Technical Parameter

| Brand | Wangzu |

| Model | Gutter Plastic formwork |

| Material | PP/ABS |

| Size | 150*30*8 |

Product Use

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are a dedicated manufacturing factory.

Q2: What services do you offer?

A: We specialize in the innovative design and robust manufacturing of formwork and scaffolding solutions. These are pivotal in the construction of concrete structures across a variety of projects, including residential properties, multi-level complexes, towering skyscrapers, elegant towers, expansive sports stadiums, intricate bridges, hydropower units, and diverse industrial structures.

Q3: How can we assist you?

A: We provide expert advice, meticulous formwork layout plans, and comprehensive cost estimations to stakeholders such as project owners, architectural design institutes, and construction contractors.

B: Our products are available for purchase by contractors, construction companies, material suppliers, and trading entities.

C: We extend support to our global partners with our high-quality formwork and scaffolding products.

D: We offer both remote and on-site guidance to construction teams to ensure flawless execution.

Q4: Can you provide samples? Are they complimentary?

A: Absolutely, we offer complimentary samples; however, the cost of freight is not included.

Q5: What information is required to draft a preliminary design and quotation for a construction project?

A: We need the structural and sectional drawings.

Q6: How long does it generally take to formulate a brief design and quotation once we provide the structural drawings?

A: Typically, it requires about 5 to 7 days, contingent upon the specific needs of the construction project.

Q7: What is the estimated timeframe for manufacturing the products after the contract is signed?

A: Generally, the production period ranges from 30 to 60 days, depending on the type and volume of products ordered.

Q8: Could you explain your payment terms?

A: For payments up to 1000 USD, full payment is required in advance. For payments exceeding 1000 USD, a 30% T/T deposit is necessary, with the remaining balance due before shipment.