close

Choose Your Site

Global

Social Media

Plastic wall formwork is a new type of building plastic specially used for cast-in-place concrete walls, suitable for construction projects, consisting of plastic formwork, inner corners, outer corners and handles. Formwork systems are becoming more and more popular in these industries and can be used to construct high-rise formwork buildings, resettlement houses, and villas.

It can be combined and adjusted according to demand, light weight, environmental protection, a person can be combined. Formwork is often used in construction and railway projects. Plastic formwork is a new material formwork system made from ABS and fiber glass,which can be reused 80-120 times.It provides project sites with convenient erection with light weight panels thus are very easy to handle.

Plastic formwork obviously improves the efficient forming of walls, columns, and slabs using a minimum number of different system formwork components.

Due to the perfect adaptability of each part of the system, the leakage of water or newly poured concrete from different parts is avoided. In addition, it is the most labor-saving system because it is not only easy to install and insert, but also light-weight compared to other formwork systems.

Other formwork materials (such as wood, steel, aluminum) will have various disadvantages, which may exceed their benefits. For example, the use of wood is quite expensive and has a major impact on the environment due to deforestation. It also saves your cost greatly compared with other material formwork systems.

Excluding the material, our developers focussed on ensuring that the formwork system was easy to handle and understand for users. Even less experienced operators of formwork systems are able to work with plastic formwork efficiently.

Plastic formwork can be recycled, in addition to reducing processing time and improving reusability indicators, it is also environmentally friendly.

In addition, the plastic template can be easily washed with water after use. If it breaks due to improper handling, it can be sealed with a low-pressure hot air gun.

1、Handier

The biggest panel is 120x60cm, weight only 10kg, which can be lift and set up by only one person easily, need no crane or other lift equipment on the site.The light weight of panels also make dismental and removing work easily.

2、EASY OPERATION

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails.

The panels have holes to fit tie rod, guarantee the strength of the whole system.

3、MODULAR

Modular formwork composed by different size of panels, the main item is 120×60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 18×60 panel (18x60cm), 20×60 panel (20x60cm), 25×60 panel (25x60cm), 30×60 panel (30x60cm), 40×60 panel (40x60cm) inner corner (25x60x10cm) and outer corner (25x60cm), and so on. Due to the variety of panel size, the system can form almost all size walls interval by 5cm.

4、STRENGTH

The material of modular formwork is ABS which enable panels to hold high pressures to 60KN.

The handles are made by high strength Nylon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

5、ENVIROMENTAL FRIENDLY

The system need not cut and nail due to the variety size, and nearly need no wood, thus keep the site of construction tidy and clean.

The material can be recycled when used out, so to minimize the possibility of polluting enviroment.

6、CONSEQUENT

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water after using.

The surface of finished wall which built by modular formwork is smooth, can be left without rework.

7、LOW COST

When it is used for over 10 times,the engineering cost is equal to the wood formwork.When it is used for over 100 times,the cost of per square will reduce 64%.It's very economic effective.

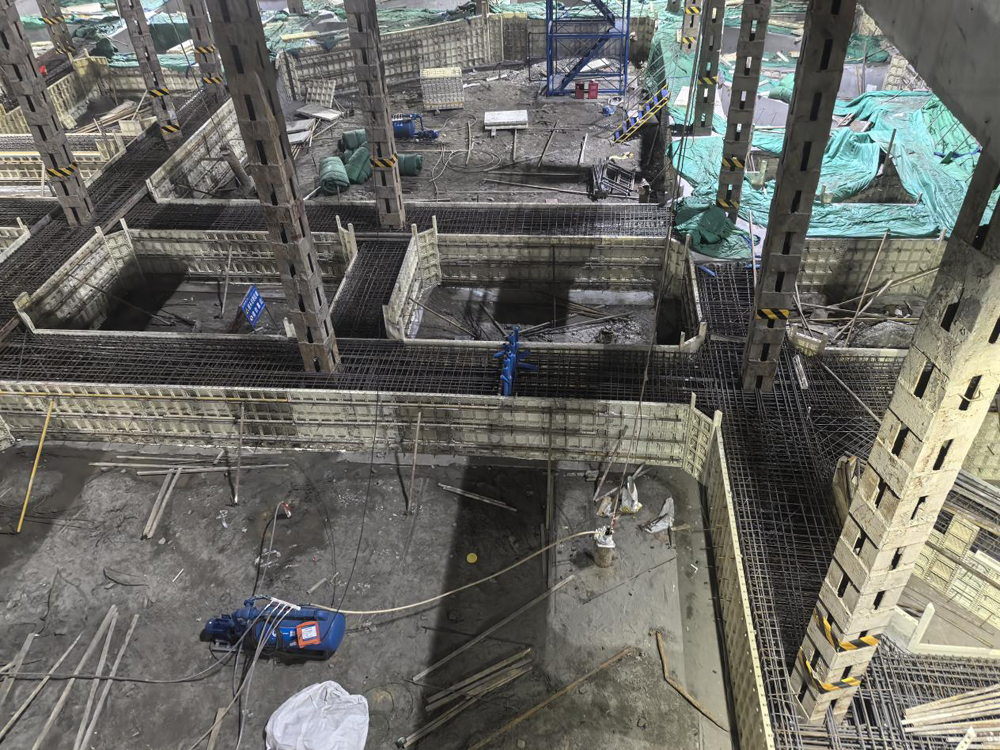

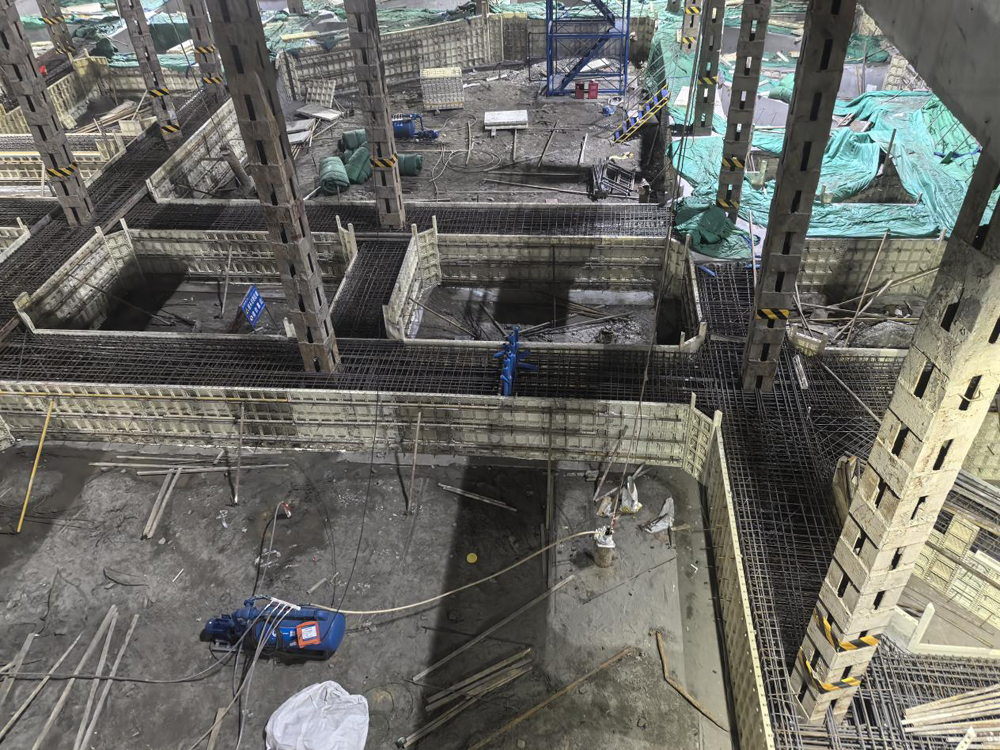

Application scenarios

Company Profile

Our company is a professional modular plastic formwork manufacturer,it was founded in 2003 and has 80 workers,covers 50000 square meters.It is located in Jiaxing that is near to Shanghai.

Our main product is plastic mould,we also have highway mould,high speed railway mould,slope protection mould,plastic turnover box and so on.There are more than 10 sets of small injection moulding machines ranging from 300 to 50000 grams, with a strong production and supply capacity.

Our factory has own mould research and development center.You can customize what you need.

We have achieved a lot of reputation,such as HI-TECH enterprises and SMEs IN Specialised New Sectors.Molds of the company have been widely and successfully used in many national key projects in China, and have been well received. In addition, our plastic molds have been sold overseas and have been successfully applied in railway construction projects in Kenya, Ethiopia, Vietnam.

If you are satisfied with our plastic template, you can order directly or consult plastic template related issues. We will provide you with the best plastic formwork products and services. We are happy to cooperate with you and bring you satisfactory products.

FAQ

Q1.Are you a factory or trading company?

A1:We are a factory.

Q2.How can I get your quotation?

A2.You can send us your project structural drawing or the material list for a quotation. Our engineer team will give your formwork solution.

Q3.What is the Payment term?

A3:T/T or L/C at sight. 30% Deposit for start the production ,the balance before the shipment when goods are ready.

Q4.How long is our Production leading time?

A4:within 15-20 days upon receive deposit in normal season, and 25-30days in our busy time(August,September,October).

Q5.What is the package method?

A5:Our products are usually packed in bulk and on pallets which suits to container transportation.

Q6: Do you have any guarantee on the quality?

A6:We guarantee the quality of different products. If necessary, you can arrange a third-party company to inspect the product quality in our factory.

Q7: What benefits can you offer us?

A7:We can provide you with perfect service, including design, production, delivery and after-sales, good product quality and reasonable price.

Q8: Are you looking for agent or distributor in our country?

A8:Yes, we are looking for an agent or distributor worldwide based on a win-win relationship.

Q9.What is the Trade Term?

A9:Ex-work factory , FOB Shanghai, FOB Ningbo.

Plastic wall formwork is a new type of building plastic specially used for cast-in-place concrete walls, suitable for construction projects, consisting of plastic formwork, inner corners, outer corners and handles. Formwork systems are becoming more and more popular in these industries and can be used to construct high-rise formwork buildings, resettlement houses, and villas.

It can be combined and adjusted according to demand, light weight, environmental protection, a person can be combined. Formwork is often used in construction and railway projects. Plastic formwork is a new material formwork system made from ABS and fiber glass,which can be reused 80-120 times.It provides project sites with convenient erection with light weight panels thus are very easy to handle.

Plastic formwork obviously improves the efficient forming of walls, columns, and slabs using a minimum number of different system formwork components.

Due to the perfect adaptability of each part of the system, the leakage of water or newly poured concrete from different parts is avoided. In addition, it is the most labor-saving system because it is not only easy to install and insert, but also light-weight compared to other formwork systems.

Other formwork materials (such as wood, steel, aluminum) will have various disadvantages, which may exceed their benefits. For example, the use of wood is quite expensive and has a major impact on the environment due to deforestation. It also saves your cost greatly compared with other material formwork systems.

Excluding the material, our developers focussed on ensuring that the formwork system was easy to handle and understand for users. Even less experienced operators of formwork systems are able to work with plastic formwork efficiently.

Plastic formwork can be recycled, in addition to reducing processing time and improving reusability indicators, it is also environmentally friendly.

In addition, the plastic template can be easily washed with water after use. If it breaks due to improper handling, it can be sealed with a low-pressure hot air gun.

1、Handier

The biggest panel is 120x60cm, weight only 10kg, which can be lift and set up by only one person easily, need no crane or other lift equipment on the site.The light weight of panels also make dismental and removing work easily.

2、EASY OPERATION

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails.

The panels have holes to fit tie rod, guarantee the strength of the whole system.

3、MODULAR

Modular formwork composed by different size of panels, the main item is 120×60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 18×60 panel (18x60cm), 20×60 panel (20x60cm), 25×60 panel (25x60cm), 30×60 panel (30x60cm), 40×60 panel (40x60cm) inner corner (25x60x10cm) and outer corner (25x60cm), and so on. Due to the variety of panel size, the system can form almost all size walls interval by 5cm.

4、STRENGTH

The material of modular formwork is ABS which enable panels to hold high pressures to 60KN.

The handles are made by high strength Nylon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

5、ENVIROMENTAL FRIENDLY

The system need not cut and nail due to the variety size, and nearly need no wood, thus keep the site of construction tidy and clean.

The material can be recycled when used out, so to minimize the possibility of polluting enviroment.

6、CONSEQUENT

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water after using.

The surface of finished wall which built by modular formwork is smooth, can be left without rework.

7、LOW COST

When it is used for over 10 times,the engineering cost is equal to the wood formwork.When it is used for over 100 times,the cost of per square will reduce 64%.It's very economic effective.

Application scenarios

Company Profile

Our company is a professional modular plastic formwork manufacturer,it was founded in 2003 and has 80 workers,covers 50000 square meters.It is located in Jiaxing that is near to Shanghai.

Our main product is plastic mould,we also have highway mould,high speed railway mould,slope protection mould,plastic turnover box and so on.There are more than 10 sets of small injection moulding machines ranging from 300 to 50000 grams, with a strong production and supply capacity.

Our factory has own mould research and development center.You can customize what you need.

We have achieved a lot of reputation,such as HI-TECH enterprises and SMEs IN Specialised New Sectors.Molds of the company have been widely and successfully used in many national key projects in China, and have been well received. In addition, our plastic molds have been sold overseas and have been successfully applied in railway construction projects in Kenya, Ethiopia, Vietnam.

If you are satisfied with our plastic template, you can order directly or consult plastic template related issues. We will provide you with the best plastic formwork products and services. We are happy to cooperate with you and bring you satisfactory products.

FAQ

Q1.Are you a factory or trading company?

A1:We are a factory.

Q2.How can I get your quotation?

A2.You can send us your project structural drawing or the material list for a quotation. Our engineer team will give your formwork solution.

Q3.What is the Payment term?

A3:T/T or L/C at sight. 30% Deposit for start the production ,the balance before the shipment when goods are ready.

Q4.How long is our Production leading time?

A4:within 15-20 days upon receive deposit in normal season, and 25-30days in our busy time(August,September,October).

Q5.What is the package method?

A5:Our products are usually packed in bulk and on pallets which suits to container transportation.

Q6: Do you have any guarantee on the quality?

A6:We guarantee the quality of different products. If necessary, you can arrange a third-party company to inspect the product quality in our factory.

Q7: What benefits can you offer us?

A7:We can provide you with perfect service, including design, production, delivery and after-sales, good product quality and reasonable price.

Q8: Are you looking for agent or distributor in our country?

A8:Yes, we are looking for an agent or distributor worldwide based on a win-win relationship.

Q9.What is the Trade Term?

A9:Ex-work factory , FOB Shanghai, FOB Ningbo.